OUSTANDING PERFORMANCE ON A BOOSTER GYPSUM SLURRY

The Customer:

Innophos Fosfatados de Mexico

Country:

Mexico

Market:

Phosphoric Acid, Phosphates

Application:

Gypsum Potash, booster pump

Equipment: :

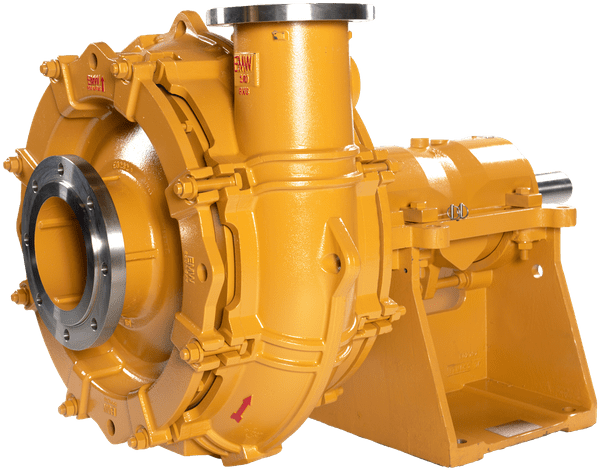

EMW300M, 12” x 10”, 750 Hp, EM450 material

Background

Innophos is the biggest phosphoric acid manufacturer in the southeastern part of Mexico. They needed a reliable booster pump to transfer gypsum to its tailings pond located far away from the manufacturing plant. The gypsum flow level increases with usage and it was at a point where only using one single pump could not handle the required head and flow. Innophos was also needing costly maintenance every four months due to the previous pump’s wearing and erosion issues.

The Challenge

Gypsum slurry is a complex solution to pump due to the combination of high corrosion and abrasion. In addition, Innophos’ raw material contains contaminants like chlorine, fluorine, and organic matter that made this application more challenging. Innophos was also looking to have a pump with extended wear life, with the minimum stops for maintenance, and with minimum expenses in spare parts.

The Solution

The Wilfley team selected a Wilfley Heavy Duty slurry pump model EMW300 constructed in EM45 material with a hardness higher than the stainless and super duplex and also corrosion-resistant to the Gypsum slurry. The pump is operated with a VFD to increase the speed as needed to overcome future increases in the system head.

The Result

The selected pump has been in operation for two years with no sign of problems of erosion on the pumps components or leaks through the mechanical seal. The customer is pleased with the pump wear life in service, creating savings in spare parts and labor costs. External indicators like vibration or power consumption are not providing signals of deterioration so they are not planning to open the pump any time soon.

Model EMW

Heavy Duty Slurry Pump with abrasion resistant materials and the Wilfley Waterless Sealing Technology

The Wilfley EMW has being designed with the latest flow modeling technologies and finite element analysis to create a pump with optimum wear life. The type of design, combined with hard iron materials or elastomer lining, creates the ideal slurry pump for high wear applications.

Wilfley EMW Pump

Key Features / Benefits

- Waterless Sealing Technology

- Leakless seal operation

- High durability

- High Chrome and elastomer lined constructions

- High Efficiency, low energy consumption

- Design for up to class 4 slurry services

- Heavy-Duty bearing offer LB10 bearing life of more than 50,000 hours