Wilfley’s chemical processing pumps have been setting the standards for concentrated nitric acid pumping since the 1930’s

Market:

Nitric Acid

Product:

Model A7 and A9

Country:

USA

BACKGROUND

Nitric acid (HNO3), also known as aqua fortis (Latin for “strong water”) and spirit of niter, is a highly corrosive mineral acid.

The pure compound is colorless. Most commercially available nitric acid has a concentration of 68% in water. When the solution contains more than 86% HNO3, it is referred to as fuming nitric acid. Depending on the amount of nitrogen dioxide present, fuming nitric acid is further characterized as red fuming nitric acid at concentrations above 86%, or white fuming nitric acid at concentrations above 95%.

Nitric acid is the primary reagent used for nitration – the addition of a nitro group, typically to an organic molecule. While some resulting nitro compounds are shock- and thermally sensitive explosives, a few are stable enough to be used in munitions and demolition, while others are still more stable and used as pigments in inks and dyes. Nitric acid is also commonly used as a strong oxidizing agent.

CHALLENGES

Wilfley’s dynamic sealing technology in combination with the Drylock static seal with Kalrez elastomer, offers a leak free pumping system without the use of flush water. Pumps run without any external flushing system, providing a reliable operation 24/7 reducing maintenance time and costs. Wilfley recommends 304L, 316L or Alloy 20 metallurgy for the wetted components of the pump. Wet end o-ring material should be Kalrez. The impeller should have balance holes. The power frame (A7/A9) should be the two piece bearing frame (CD4 bracket / DI frame). Both the pump casing and expeller chamber should have drains. The recommended seal type is the DryLock 3. The seal housing design should include a drip lip to keep condensed nitric acid from accessing the seal faces. Due to the corrosive nature of nitric acid and nitric acid fumes, sintered silicon carbide is the recommended seal face material.

THE RESULT

Based on over 80 years of successful installations using the Wilfley Legacy Products (AC, AF, and AG), the modern Wilfley A7 and A9 product lines are the culmination of the combined chemical, physical, and operational experience we’ve gained. Pumps selections for nitric acid service today optimize metallurgy, design features, and operational criteria, making Wilfley a leader in pumps supplied for this most challenging service.

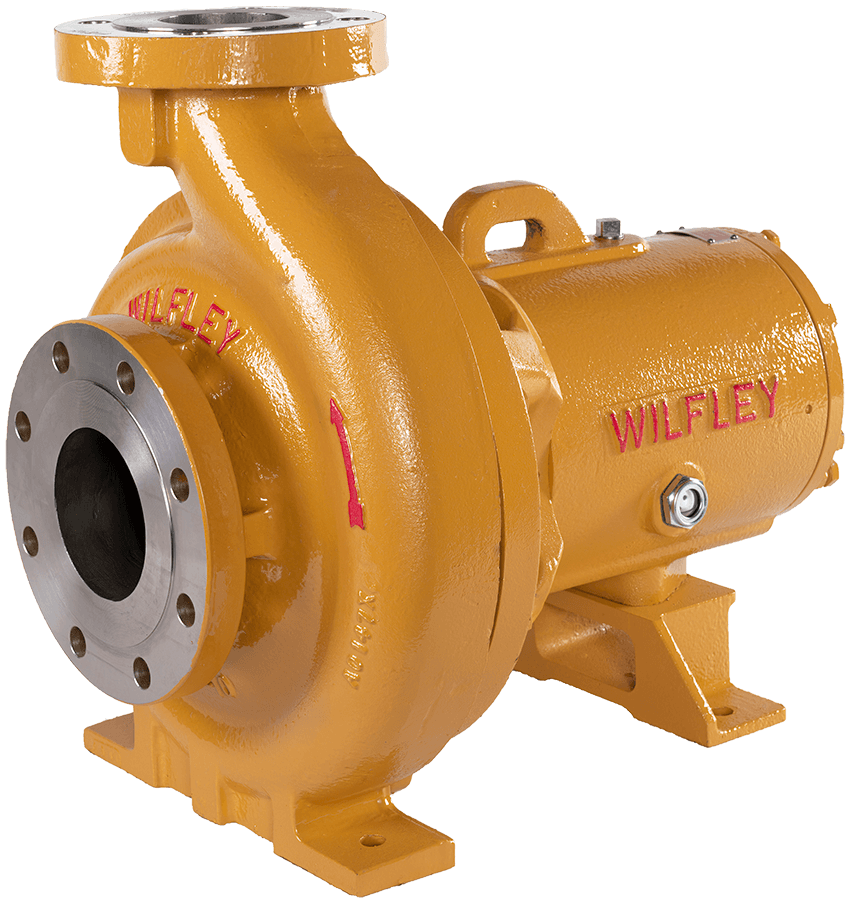

A9 CHEMICAL PUMP

Durability and Waterless Sealing for Tough Pumping Applications

The Robust wet end construction of the EMW pump built to last and features components with double the thickness of comparable medium duty slurry pumps, combined with Wilfley’s proprietary Maxalloy 5A hard iron and elastomer liners, creates the ideal slurry pump for abrasive applications.

The Wilfley A9 pump meets and exceeds the ANSI B73.1 standard. Its robust design, reliable seal, and durable metallurgy offers an unmatchable solution for demanding industrial and mining applications.