Driver Constants

Growing concerns over energy use and efficiency have fueled more widespread use of variable speed systems to power centrifugal pumps. There are several factors at play, but the design freedom permitted by breaking the bonds to fixed electrical frequencies can help get closer to the pump Best Efficiency Point, or BEP. However, there are some mathematical sharks lurking below the surface that need to be considered.

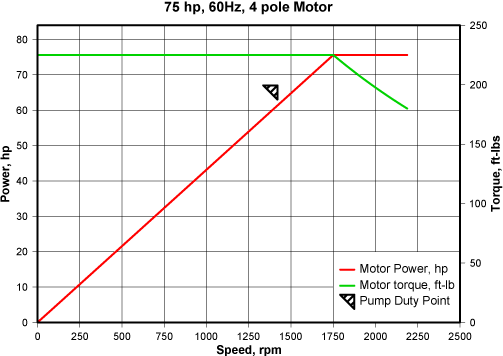

Electric motors are the most common (electro-) mechanical devices used worldwide. In particular, induction alternating current (AC) motors are the most common pump drivers and fortunately they exhibit some relatively simple traits. When operated below rated speed, they produce constant torque; above rated speed the power output is constant.

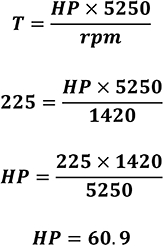

The relationship of power output to torque is defined as:

![]()

(US units, ft-lb)

![]()

(SI Units, N-m)

For example, a 75 hp / 1,750 rpm motor is capable of 225 ft-lb of torque. Similarly, a 55 kW / 1,450 rpm motor is capable of 362 N-m of torque. Considering the traits and equation above, a motor’s output can be graphically demonstrated below:

Most pump manufacturers choose to fix the pump diameter at maximum values when sizing for variable speed applications to reduce the number of iterations and maximize efficiency. And inconveniently enough, the resultant speeds rarely fall at or near fixed frequency motor speeds.

Consider a pump that requires 67 hp (50 kW) at 1,420 rpm, for illustration. What motor do you choose? Would the example motor above provide enough power at the rated pump speed? Knowing that torque is constant below rated frequency, we can use the equation above to determine if this motor will work.

Therefore, a 75 HP, 1750 rpm motor can only produce 60.9 HP at 1,420 rpm and will not work. But a 100 HP, 1750 rpm motor is capable of producing 81.1 HP at the rated pump speed and therefore will work. Below is a quick and easy calculator to help you select the correct motor for your application.

Variable Speed Motor Calculator:

| Unit of Measure: | |

| Motor Rated Frequency: | |

| Pump Rated Speed (RPM): | |

| Pump Rated Power: | |

| 2 Pole Motor: | |

| Minimum Rating Required: | |

| Full Coverage Rating: | |

| 4 Pole Motor: | |

| Minimum Rating Required: | |

| Full Coverage Rating: | |

| 6 Pole Motor: | |

| Minimum Rating Required: | |

| Full Coverage Rating: | |

Notes:

- Minimum Rating Required refers to the motor size required to deliver enough power to operate the pump conditions as input. Please note that pump power requirements increase exponentially with speed – consider all operating points carefully.

- Full Coverage Rating refers to the motor size required to accommodate up to full speed (0-100%) range of the motor, by applying the Affinity Laws for centrifugal pumps.

- For most applications, using maximum power values (non-overloading) for the rated impeller diameter and speed is recommended.

- Most VFD-rated motors are capable of 20% overspeed (consult motor manufacturer). If pump rated speed is greater than 120% of motor full speed, no motor is recommended.

- A “Not Recommended” message will appear if the power requirement exceeds 400 HP (300 kW), which exceed NEMA or IEC standard frames.

- Although centrifugal pumps are variable torque loads, constant torque methods are being applied for conservative reasons.