CALCIUM CARBONATE

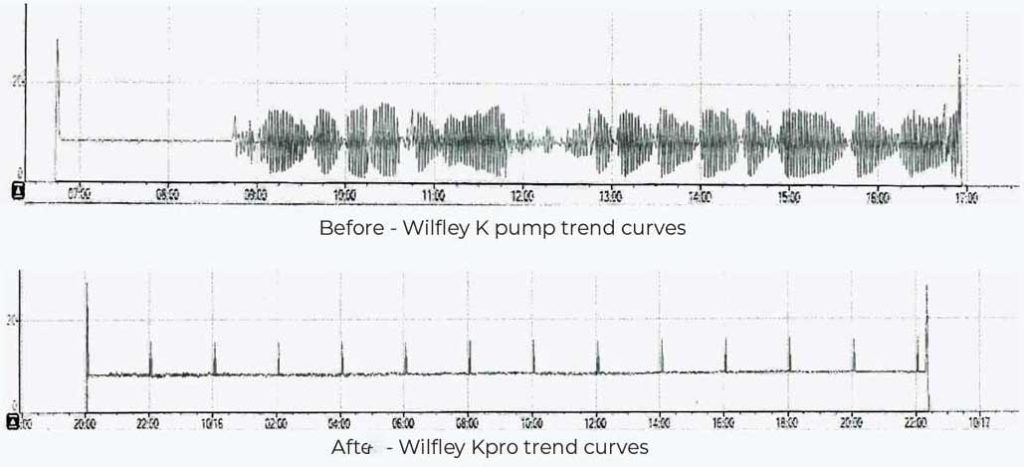

Wilfley Revolutionary Froth Impeller helped customer to avoid pump vapor locking and created very stable operation

Market:

Calcium Carbonate

Application:

Hot Froth Slurry

Equipment: :

Kpro pump, Maxalloy 5, Wilfley Waterless Seal Technology

Country:

USA

Background

Calcium Carbonate (CaCO3) constitutes more than 4% of earth crust. Almost every product in our day-to-day life contains Calcium Carbonate, like Metallurgy (mainly steel manufacture), Environmental Uses (Soda Ash, Soften Water, WWT and FGD), Chemical and Industrial like paper manufacturers, Paint, Coatings, Sugar Refinery, Construction (Asphalt, Stabilize Soils Mortar and Plaster, Ceramic, Cable, Flooring, Coated Fabrics, etc.). OMYA is the World leading CaCO3 producer with more than 180 plants over 50 countries. 2018 Global CaCO3 market size was 22.95 Billion and is estimated to witness CAGR of 7.4% from 2019 to 2025.

The Challenge

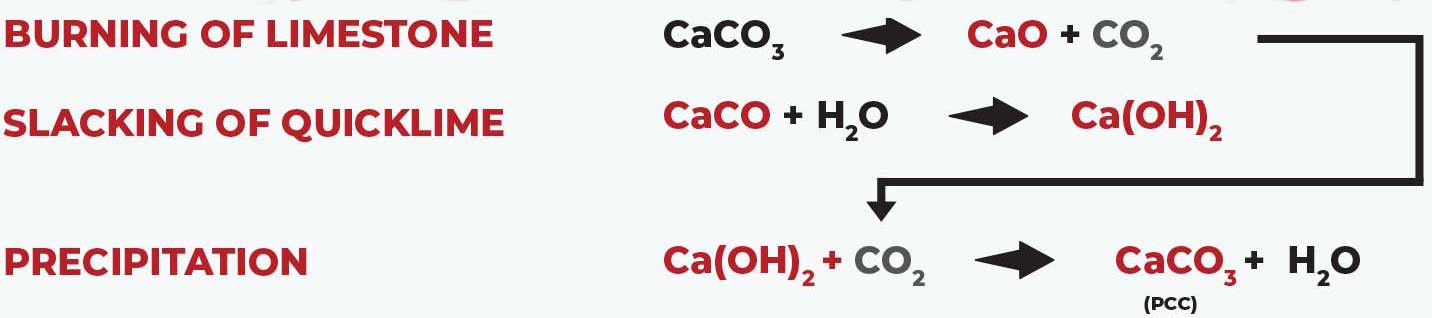

Precipitated calcium carbonate (PCC) is an innovative product derived from lime. Limestone is converted into calcium oxide and carbon dioxide by means of calcination at temperatures in excess of 900°C. To ensure a high level of purity, the calcination process is carried out using natural gas. After the calcined lime has been slaked with water, the resulting milk of lime is purified and carbonated with the carbon dioxide obtained from the calcination process (See reactions below).

Precipitated CaCO3 is a water base slurry (high percentage very fines solids) which requires Slurry Pumps use most of the time. Production processes combine a frothy slurry with high temperatures close to water boiling point (212 F), increasing the mix vapor pressure which reduces NPSH available. It is difficult to pump due to high probability of cavitation and vapor locking, plus wear if not using correct pump material of selection.

The Solution

Wilfley developed a special froth impeller for the Kpro pump (Upgraded K side suction pump) which allow to keep the mix (air + liquid phase) together while holding customer operating conditions near cavitation. Pumps are made in Maxalloy® 5 (27CH Hard Iron) Wet End with Wilfley proprietary WCD4® (Hardened CD4MCuN, Duplex Stainless Steel with 345HBN) impeller, Wilfley Dynamic Seal plus Solidlock® Static Seal, no seal flush needed, no dilution caused.

Since pump was installed customer started to see results of more stable operation and after a year using the pump, customer decided to buy for more pumps for different plant locations where they have similar froth problems.

FROTH HANDLING K & KPRO SLURRY PUMPS.

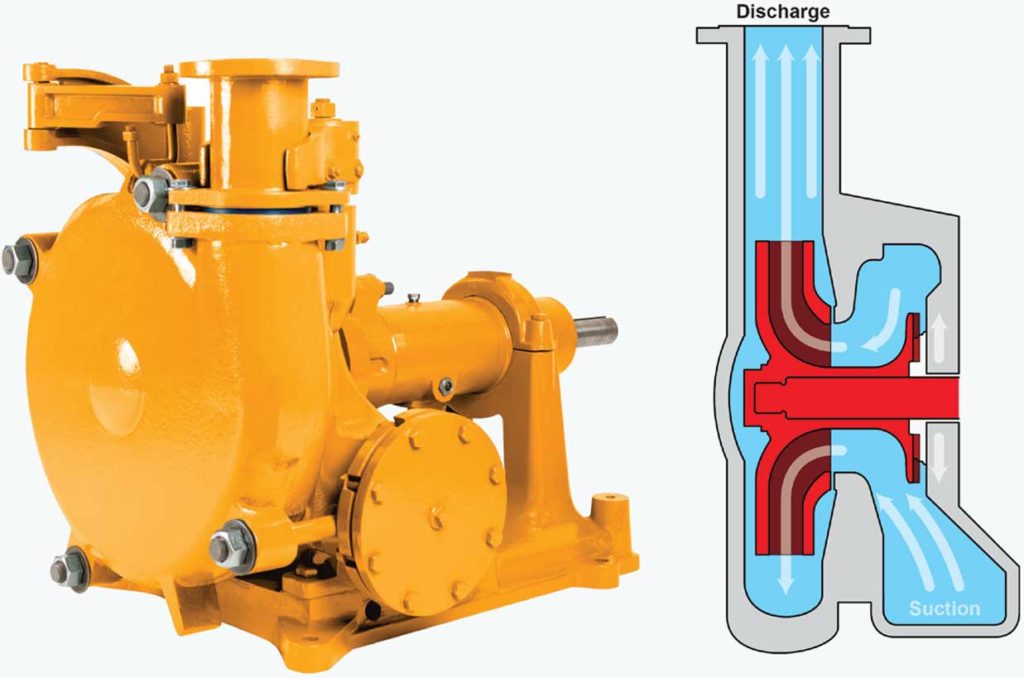

A key design requirement for good froth handling is low fluid velocity into the impeller. As fluid enters the impeller, it is accelerated by the impeller; as the velocity increases, the static pressure of the fluid decreases. This lower pressure allows the air in the froth to expand as it enters the impeller; it becomes a larger fraction of the total flow and acts to choke the impeller eye. This causes decreased pump performance and can also result in air pockets within the case, leading to loss of prime.

THE SIDE-SUCTION DESIGN OF THE KPRO ADDRESSES INLET VELOCITY IN TWO WAYS:

- The large volume of the side-suction inlet provides a high inlet area to discharge ratio. This reduces velocity through the inlet, keeping the gas entrained within the froth as it flows through the pump.

- The side-suction design brings the fluid into the pump in close proximity to the dynamic seal, which, being open to atmosphere, prevents the pump from building suction pressure. This minimizes the pressure differential between the inlet and the impeller, further keeping the gas entrained in the froth.

- The Kpro impeller features a wide impeller eye and large impeller vane passages. Velocities through the impeller vanes themselves are minimized, due to the high volume available for the fluid to pass through. Therefore, the entrained gasses are less likely to expand as they flowthrough the impeller and out of the pump.

Wilfley Model Kpro

Key Features / Benefits

- Waterless sealing technology.

- A maintenance engineer’s delight

- Case can be easily removed without disturbing suction or discharge piping

- Wear resistance materials