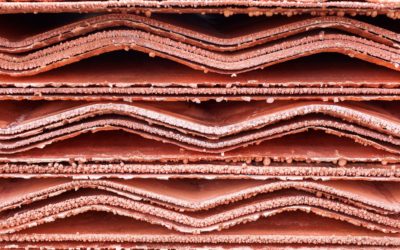

Copper

Copper

Water supply plays an important role in all copper mining ventures, particularly with projects in water scarce regions. Most water in copper mining is used in flotation beneficiation, smelting, and electro-refining.

Wilfley Heavy Duty centrifugal pumps with its waterless seal system and durable construction is not only helping Copper mines worldwide to meet water consumption regulations and but also increasing plants reliability by eliminating bearings contamination due seal / gland packing leakages.

Processes

- Copper concentrate

- Molybdenum

- Heap leaching

- Solvent extraction

- Electrowinning

- Copper refinery

- Milk of lime

- Dore plant

- Froth handling

Wilfley Copper Industry Case Studies

Doré Plant

WCD4™ IMPROVES 400% WEAR LIFE

Codelco Chuquicamata is the largest open pit copper mine in the world, located in the north of Chile, just outside Calama. It began operations in 1952 and has copper reserves of 40 years.

Filter Feed Application

ONE WILFLEY EMW200 SAVES MORE THAN 500,000 GALLONS OF WATER IN ONE YEAR

Grupo Mexico is the largest mining corporation in Mexico and the third largest copper producer in the world. Its Buenavista del Cobre mine is located in the north-west of Mexico, in a dry and desertic area.