In Part 1, we discussed the driving factors for increasing fluid temperature as flow is decreased through a centrifugal pump. For convenience, water was considered as the fluid in the examples given. Although water is the world’s most prevalent liquid, it’s also the easiest to handle, both from a pump and seal point-of-view. When applications get tough, customers often approach Wilfley as demonstrated in this post.

Just a few years ago, a long-time Wilfley customer in Canada was implementing intrinsic safety monitoring on critical services in their fertilizer plant. On one molten urea application where a Wilfley AG chemical pump had been reliably providing service for over 30 years, they sought to understand the potential thermal risks.

The specific application utilized a large frame 2 ASME pump (4×3-10) rotating at 3,550 rpm pumping molten urea. The fluid temperature was near 300°F (149°C) with a specific gravity of approximately 1.2. Fortunately, the customer’s conditions were at the pump’s best efficiency point and the temperature added to the fluid was a less than 1 degree.

How does molten urea differ from water? For starters, it is over 20% more dense than water, which works in our favor for temperature rise as there is more mass to transfer heat. On the other side, the specific heat (CP) is almost twice as sensitive as water (0.56).

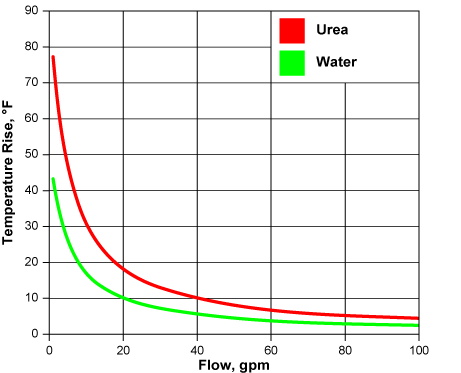

Comparative Temperature Rise

As you can see from the chart, the temperature rise for the pump in this application is significant. The temperature rise values are calculated per the equations provided last month (if liquid is moving thru the pump):

ΔT = H/ (778xCP)*(1/ƞ-1) for Imperial Units

ΔT = H/ (432xCP)*(1/ƞ-1) for Metric Units

At shut-off (zero flow) conditions, the liquid is not able to remove heat build-up within the pump case via mass transfer. A different equation is employed:

ΔT = (HPSO*5.1)/ (V*sg*CP) for Imperial Units

ΔT = (kWSO*60)/ (V*ρ*CP) for Metric Units

Where:

ΔT = Temperature rise in °F / minute or °C / minute respectively

V = Pump contained volume, from flange to flange in US gallons or cubic meters

sg = Specific gravity

ρ = Sensity in kg/m3

CP = Specific heat in BTU/ (lb °F) or kJ/ (kg K)

In this example, the molten urea temperature rise at shut-off (zero) flow exceeds 322°F (179°C) per minute of operation! Compare this to water at 216°F (120°C) per minute rise.

A multiplicity of factors converge as temperature rises so quickly, from potential rapid decomposition of the liquid (i.e. explosion) compounded with reducing material strength of the pump components (fasteners, case wall, etc) and even corrosive process acceleration to name a few.