The widely referenced centrifugal pump standard known as ASME B73.1 can trace its origins as early as 1955, when efforts to develop chemical pump standards began. This later evolved into the American Voluntary Standard in 1962 and, in conjunction with a similar Hydraulic Institute standard, became ANSI B73.1 in 1974. This standard has gone thru several iterations over the years, with the current version first published in 2012: Specification for Horizontal End Suction Centrifugal Pumps for Chemical Process.

In the ISO community, standard 2858 was first published in 1973 and contained dimensional (bare pumps only) and nominal duty points, but free of technical requirements. It wasn’t until 1986 that construction standards were published for ISO pumps as “Technical specifications for centrifugal pumps – Class II”. The current version (second edition) was issued for publication in 2002.

Both standards are widely referenced worldwide for centrifugal pump projects, even outside of chemical process applications. The basic construction is the same: end suction, centerline (self-venting) discharge, back pull-out and frame mounted. However, often the two international standards are divided by the electrical frequency applicable: B73.1 for 60Hz and ISO 5199 for 50Hz. However, either standard can be applied to applications involving either frequency, especially as VFD’s are becoming more common.

Sizes and Dimensions

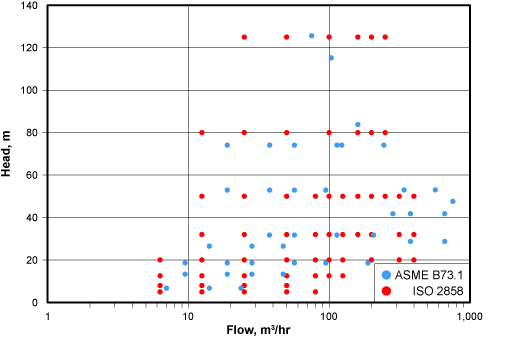

When measured by pure numbers, ISO 2858 as referenced within ISO 5199 accounts for more discrete models (34 sizes) than B73.1 (27 sizes). Technically, five sizes are listed as “optional” in ISO 2858. Dimensionally, the ISO specification has just as many dimensional differences as pump sizes: 34. Contrast this with B73.1 that fits the 27 sizes into 17 different size designations. As it relates to baseplates, ASME B73.1 includes dimensional envelopes within its specification whereas a separate ISO document is used to convey this requirement: ISO 3661.

Design Points, 50Hz

Technical Summary (ASME B73.1 vs ISO 5199)

| Reference | ISO | ASME |

| Flange Ratings* | PN16 (16 bar) | B16.5 Class 150 or 300 |

| Temperature Range | Not specified | Up to 260°C |

| Bearing L10 Life, hours** | 17,500 | 17,500 |

| Hydrotest Pressure | 150% of MAWP for 10 minutes | 150% of MAWP for 10 minutes |

| Future Head Capability | 5% | No Specified |

| NPSH Margin, Minimum | > 0.5 m | > 0.9 m |

| Driver Sizing, % of Pump Rated Input | 137% < x > 110% | Not Specified |

| Critical Speed Margin, Minimum | 10% | 20% |

| Balance Specification | Not Specified | ISO 1940 G6.3 |

| Vibration Level, Maximum | 3.0 mm/sec for <= 225 mm centerline 4.5 mm/sec for > 225 centerline | 4.8 mm/sec for < 200 kW 5.6 mm/sec for >= 200 kW |

| Corrosion Allowance, Minimum | 3 mm | 3 mm |

| Shaft Deflection, Maximum | 0.05 mm | 0.13 mm |

| Shaft Run-Out, Maximum | 0.05 mm up to 50mm OD 0.08 mm up to 100mm OD 0.1 mm over 100 mm | 0.025 mm on centers 0.05 mm installed |

| Thrust Bearing Locking Mechanism | No circlips permitted | Not Specified |

| Bearing Isolators | No lip seals permitted | Not Specified |

| Rotation | CW | CW |

This summary is not intended to be an exhaustive review of the differences between the two standards. Bold values indicate a more stringent requirement.

Notes:

(*) – Nominally, the casing wall, sealing cover and gland should be rated to at least the pressure temperature rating of the flanges. ASME B73.1 requires Class 150 flanges for ductile iron and alloy steels as a minimum (280 psig /19.3 bar) at ambient temperature. ISO 5199 specifies PN16 flanges (16 bar / 232 psig). Although neither specification is limited to applications for 50Hz countries, generally speaking ASME B73.1 pumps are designed to meet 60Hz conditions which require thicker casing walls and higher rated flanges.

(**) – Both specifications require a minimum 17,500 hours of bearing life. However, when comparing designs intended for 50Hz to 60Hz, please note that bearing L10 life is influenced by the speed of the pump. Therefore a pump designed for 4 pole, 60Hz speed and 17,500 hours L10 will theoretically provide for 62,650 hours at 4 pole 50Hz speed.