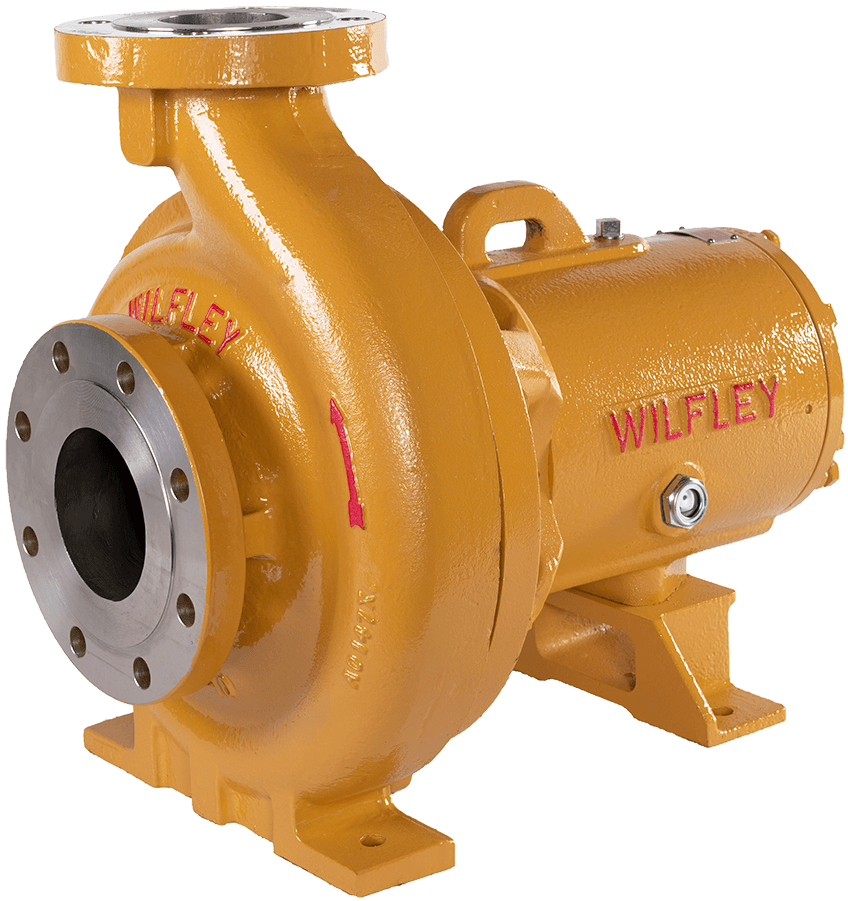

A9 CHEMICAL PUMP

Durability and Waterless Sealing for Tough Pumping Applications

The Wilfley A9 pump meets and exceeds the ANSI B73.1 standard. Its robust design, reliable seal, and durable metallurgy offers an unmatchable solution for demanding industrial and mining applications.

Main Benefits

- Waterless Sealing Technology

- Leakless seal operation

- Operational abuse tolerant

- Product dilution eliminated

- Wear resistance material of construction

- Heavy-Duty construction

- Reduced maintenance cost and maximized production time through increased mean time between maintenance (MTBM)

- Robust shaft design with lower L3/D4 stiffness ratios and lower deflections

- Longer L10 bearing life

Main Applications

- Clean or contaminated liquids

- Abrasive and corrosive applications

- Crystalizing solutions

- Uploading and downloading

- Highly realiable equipment applications

- Viscous liquids

Key Characteristics

Capacities:

Flows up to 7,100 usgpm (1,613 m3/h)

Heads:

Heads up to 735 ft (224 m)

Max Working Pressure:

350 Psig (24 Bar)

Max Temperature:

400°F (205°C)

Discharge Sizes:

From 1″ (25 mm) to 8″ (203 mm)

Heavy duty case design with 150 lb. flanges

(300 lb. flanges available)

Comprehensive Hydraulics

Available to meet your needs

Pressure / temperature balance holes

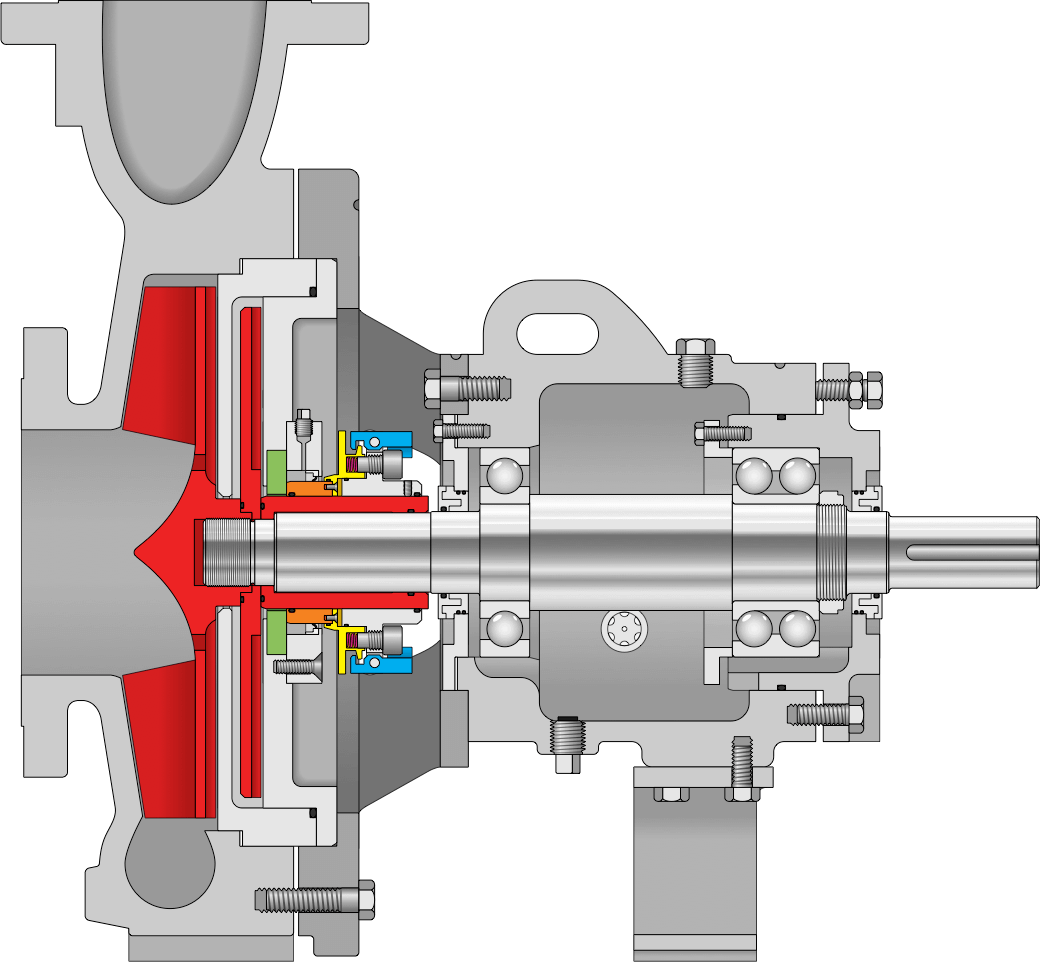

Opti-expeller

Provides superior dynamic sealing with zero operational leakage

Solidlock® seal

Engineered for reliable static sealing

Seal wash out capability

Robust shaft with L3/D4 ratios

Minimized deflections and increases seal life and relability

Frame bracked

Designed to protect bearing unit from pumpage (duplex stainless steel optional)

Convenient lifting point

Large sight glasses

On both sides to easy verify oil level

303SS labyrinth seals

Prevent oil contamination

Easy clearance adjustment

Via external adjustment bolts

Waterless Sealing: Wilfley’s Technological Advantage

The Wilfley Waterless Seal Technology is a proven design combining a dynamic and static seal, that excels in demanding applications and is trusted by companies all over the world.

Materials Options

- Duplex Stainless Steels

- Austenitic Stainless Steels

- Nickel Alloys

- High-Chrome Hard Irons

Seal Options

- Wilfley Waterless Seal Technology

- Expeller with Packing

- Mechanical Seal

- Solidlock

- Drylock II

Documents

A9 Chemical Pump Performance Range Capacities

(Rollover the dots in the chart to view more information)

Precision Engineering, Proven Reliability

The A9 pumps on the right are located in the Atacama Desert, one of the driest places in the world. They work 24/7 and the customer appreciates the Wilfley Waterless Seal Technology under these severe conditions.

Contact Wilfley for detailed specs, case studies, pricing, and customized solutions along with answers to all your questions. We are here to help you have the best options for your unique situation and operating budget.