Wilfley has recently developed and released a new extension of the widely popular and proven A9 product line… the A9LF pump. The A9LF has been specifically designed to handle the unique requirements of low-flow high-head applications. Key benefits include:

- Lower specific speeds increase pump reliability

- Higher head for a given impeller diameter

- Higher efficiency versus a traditional centrifugal pump design

- Increased L10 life of the bearings due to the significantly reduced radial loads

The A9LF pump also has all of the same features of the standard A9:

- DryLock® 2 Static Seal

- Opti-Expeller

- Extremely robust power end

Design

(Hover over or tap on image to view cross section)

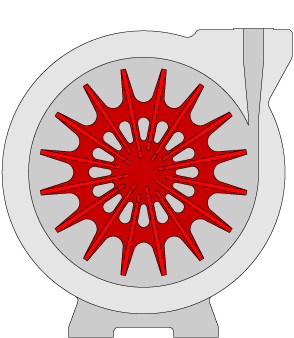

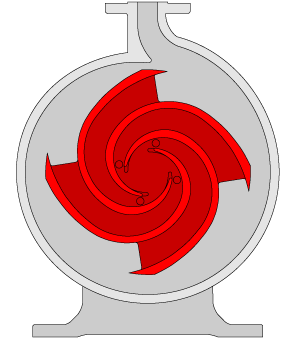

The developed heads and the efficiencies can be as much as 30-35% higher than similar diameter volute radial vane pumps at similar capacities. The radial loads are also approximately 25% of the values seen by volute style pumps. All of this is achieved with the high precision circular case design and the fully-open Barske style impeller.

A9LF Case & Impeller

Standard A9 Case & Impeller

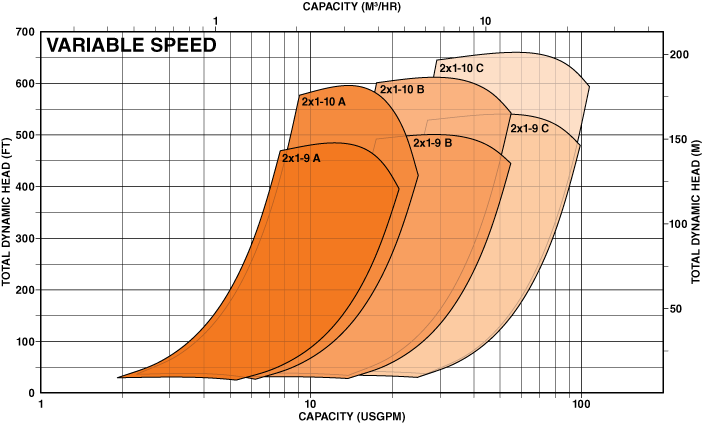

Coverage

The A9LF pump is currently available with two set impeller diameters (9” and 10”) and three discharge throat diameters (0.25”, 0.375”, 0.5”), all packaged in a 2″x1″ ANSI RF studded flange arrangement.

Specifications at a Glance

- Layout: End suction, top (tangential) discharge, back pull-out design

- Impeller: Fully-open Barske style design

- Frame: Overhung shaft, with two piece frame

- Sizes: 2×1-9 (A,B,C), 2×1-10 (A,B,C)

- Seal Options: DryLock® 2 with Opti-Expeller; single or double mechanical seals

Contact your local Wilfley representative today to learn more about the A9LF pump.