The superlative EMW® Slurry Pump, launched over a year ago, has demonstrated class leading efficiency and wear resistance in some of the most severe slurry applications in the field. Now, A.R. Wilfley & Sons, Inc. is pleased to announce the availability of a new configuration that our loyal customers have relied on for 95 years – the legendary Wilfley “seal-less” design.

The original “seal-less” pump was invented by Arthur Redman Wilfley to address problems caused by ordinary sealing technology, which still persist today. Common seals such as compression packing and mechanical seals are excessively high wear components (including shaft sleeves, lantern rings, gaskets) when operated continuously as most production facilities require.

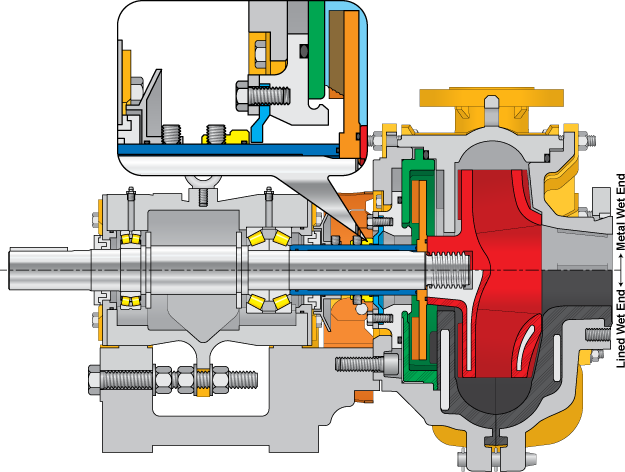

When configured for “packing-less” or “seal-less” operation, Wilfley pumps utilize a specially designed expeller to generate a dynamic seal. The dynamic sealing operation negates the need for a contacting face seal and therefore eliminates seal wear, heat generation and subsequent water flush. A static seal is activated to provide positive sealing when the pump is idle.

Static sealing options include a cost effective elastomeric diaphragm (shown below) as well as a governor-actuated “check-valve” type mechanism. Either configuration will permit flush-free operation and extend mean-time between maintenance well beyond that of traditional sealing technologies.

EMW® slurry pump with diaphragm static seal

Contact your local Wilfley representative NOW to learn more about these exciting new capabilities.

Always remember… Wilfley is a single source manufacturer, a lifetime parts supporter, and we believe that EVERY PUMP MATTERS.

Click here to learn more about the EMW® slurry pump.