Wilfley has always focused on process reliability and operational efficiency; attributes dating back to Arthur Redman’s original side suction slurry pump design and the introduction of the expeller. This relentless focus on cost effectiveness is definitely still alive and well in Wilfley’s latest innovation, the EMW® slurry pump.

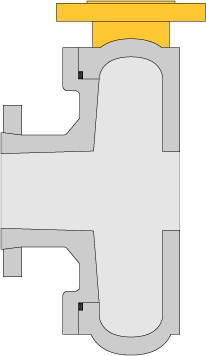

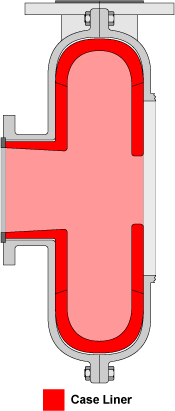

The average metal slurry pump relies on a case liner system that consists of an interior hard iron case liner that is surrounded by a low cost, ductile iron shell. Wilfley designed the EMW®, just as all their heavy duty slurry pumps, with a 100% ultra-hard iron case, which begs the question: which would you prefer, gold plated or solid gold?

EMW® Hard Iron Case

Typical Case Liner System

Economic Benefits of the EMW® Case

The theory behind the case liner system is that it is a more economical solution for the customer because they will only need to replace the liner instead of the whole case. This false economy may appear true when you compare the cost of one EMW® case to the cost of another’s case liner. However, due to the heavy duty design of the EMW® and Wilfley’s MAXALLOY® 5A hard iron, this theory doesn’t hold up when you look at the total amount spent over the life of the pump.

Total Cost after 1 Year in Service

For example, a customer replaced a competitor’s pump with a similar sized EMW® in a very abrasive, high wear application. The competitor’s case liner would typically need to be replaced every 3 weeks (roughly 17 case liners a year), while the MAXALLOY® 5A case in the EMW® would only need to be replaced every 5 weeks (roughly 10 cases a year). Even though the initial cost of the EMW® pump was higher, the EMW® generated a return-on-investment in less than 1 year due to the extended service life – even earlier if you consider the downtime costs.

Disadvantages of the Case Liner System

The EMW® case isn’t just superior in terms of operational savings; it’s also an improved design that addresses many of the prominent disadvantages with the case liner system:

- Case liners have multiple leak paths and require more temperamental gasketing. The EMW® case only requires two o rings, housed in a proper gland.

- Case liners require elastomeric rings at the flanges, which attempt to alleviate the clamping force from the liner system. This in-turn, produces an inferior flange mating surface. The patented flange arrangement of the metal EMW® case offers industry preferred raised face flanges; without stressing the hard iron.

- Case liners are more difficult to assemble and typically employ complex fastening systems.

- Case liners have a thinner wall thickness and a lower tensile strength, which makes them easier to damage during assembly.

The advantages of the EMW® heavy duty slurry pump favor users looking at the true operational costs, not just the initial price. Yet again, further proof that Wilfley pumps cost less… because they last longer.